How to Install Top Liners: Step-by-Step Guide for Installation

By:Admin

{Company Name} is a leading provider of advanced roofing solutions, offering a wide range of products and services to meet the needs of commercial and residential customers. With a focus on quality, durability, and sustainability, {Company Name} has established itself as a trusted name in the industry.

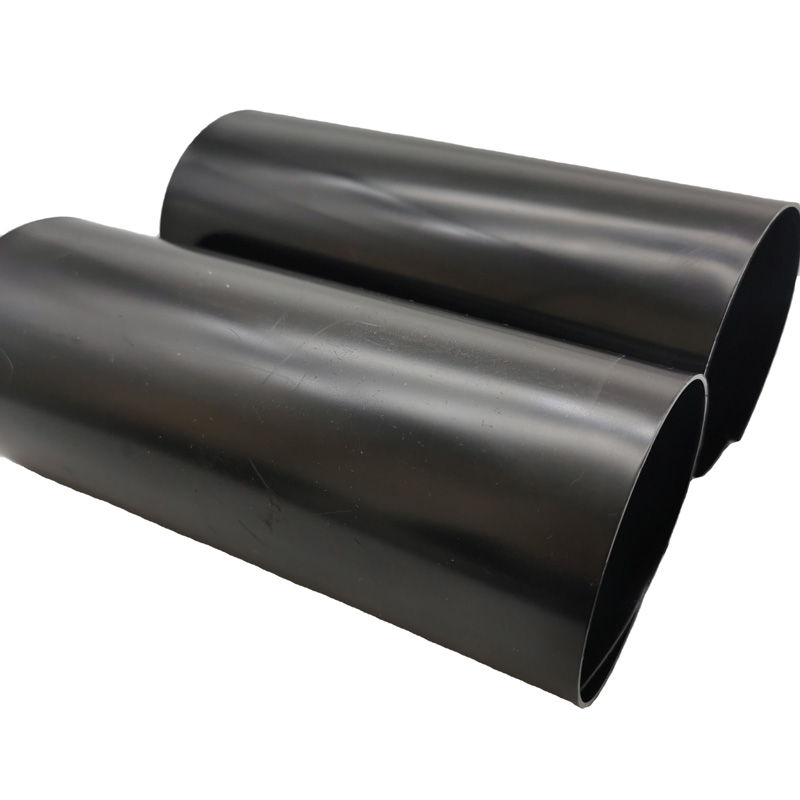

One of the key components of {Company Name}'s roofing solutions is the TPO liner, a popular choice for flat and low-slope roofing systems. TPO, or thermoplastic polyolefin, is a synthetic material known for its flexibility, heat-reflective properties, and resistance to UV radiation, making it an ideal choice for roofing applications. TPO liners are also lightweight, cost-effective and relatively easy to install, making them a popular choice for a wide range of roofing projects.

{Company Name} understands the importance of using high-quality materials in its roofing solutions, which is why they offer TPO liners as part of their product line. The company's TPO liners are manufactured to the highest standards, ensuring superior performance and longevity. Customers can choose from a variety of thicknesses and colors to suit their specific needs and preferences.

In addition to offering TPO liners as a standalone product, {Company Name} also provides professional installation services to ensure that the liners are properly fitted and sealed for maximum protection. The company's team of experienced technicians is trained to handle TPO liner installation with precision and efficiency, ensuring that the end result is a reliable and durable roofing system that will stand the test of time.

The installation process begins with a thorough assessment of the customer's roofing needs, taking into account factors such as the size and slope of the roof, as well as any specific requirements or preferences the customer may have. Once the design and specifications are finalized, the installation team gets to work, carefully laying and sealing the TPO liner to create a seamless and watertight barrier against the elements.

{Company Name} prides itself on delivering exceptional customer service, and this extends to the installation process. The company's technicians work closely with each customer to ensure that their specific needs and expectations are met, providing clear communication and reliable support throughout the installation process. {Company Name} also stands behind its work, offering warranties on both the TPO liners and the installation service to provide customers with added peace of mind.

With its commitment to quality, innovation, and customer satisfaction, {Company Name} has become a trusted partner for customers seeking reliable and sustainable roofing solutions. The company's TPO liners and professional installation services are just one example of how {Company Name} delivers on its promise to provide industry-leading products and support to its valued customers. Whether it's for a commercial or residential project, {Company Name} has the expertise and resources to create a durable and long-lasting roofing system that will stand up to the demands of the environment.

As the demand for high-performance roofing solutions continues to grow, {Company Name} remains at the forefront of the industry, offering cutting-edge products and services that meet the evolving needs of its customers. With its dedication to quality and innovation, {Company Name} is well-positioned to continue setting the standard for excellence in the roofing industry, providing customers with the peace of mind that comes with a reliable and sustainable roofing solution.

Company News & Blog

Discover Top-Quality EPDM Parts for Roofing - Boost Your Roof's Durability and Performance

[Title: Roofing EPDM Parts - Leading the Industry with Innovation and Quality][Subtitle: The Journey of {} in Transforming the Roofing Industry](Date)(Location)Roofing is an essential aspect of any building, providing protection against the harsh elements and enhancing the overall aesthetic appeal. In recent times, EPDM (Ethylene Propylene Diene Monomer) roofing systems have gained immense popularity due to their durability, cost-effectiveness, and environmentally friendly nature. This rising trend in EPDM roofing can be largely attributed to industry leaders like {}, who have revolutionized the market with their innovative and high-quality roofing EPDM parts.Established in (year), {} has been at the forefront of the roofing industry, consistently providing customers with top-of-the-line EPDM roofing solutions. With a customer-centric approach and a commitment to excellence, the company has carved a niche for itself, setting new standards in the industry.{} specializes in producing EPDM parts that are crucial to the installation, repair, and maintenance of roofing systems. These parts include, but are not limited to, flashings, membranes, adhesive tapes, sealants, and various accessories. The company's extensive range of EPDM parts caters to the diverse needs and requirements of both residential and commercial projects.What sets {} apart from its competitors is its unwavering focus on innovation and product quality. The company invests heavily in research and development to constantly evolve its range of roofing EPDM parts. By staying ahead of industry trends and technological advancements, {} ensures that its products not only adhere to the highest quality standards but also incorporate the latest advancements to meet the ever-changing demands of customers.Moreover, {} places great emphasis on sustainability and environmental consciousness. EPDM roofing systems are known for their energy-efficiency and eco-friendliness, and {} takes this a step further by implementing eco-friendly manufacturing processes. The company uses recyclable materials and endeavors to reduce its carbon footprint, contributing to a greener future.In addition to their commitment to innovation and sustainability, {} boasts an extensive network of authorized distributors and contractors worldwide. This global presence allows customers to access their high-quality EPDM parts no matter where they are located, ensuring that everyone can benefit from their exceptional products.Furthermore, {} prioritizes customer satisfaction as the cornerstone of their business. The company's dedicated customer support team is always ready to assist clients with any inquiries or technical assistance they may require. Whether it is providing guidance on product selection or addressing post-purchase concerns, {} goes above and beyond to ensure a seamless experience for their customers.As a testament to their industry-leading standards, {} has received numerous accolades and certifications over the years. These awards recognize the company's commitment to excellence, further cementing their position as a reliable and reputable provider of EPDM roofing parts.Looking ahead, {} continues to innovate and expand its product line to cater to the evolving needs of the roofing industry. By staying agile and adaptive, the company remains at the forefront of technological advancements and market trends, ensuring they are always one step ahead of the competition.In conclusion, {} has emerged as a trailblazer in the roofing industry, leading the way with their innovative and high-quality EPDM parts. With a customer-centric approach, a focus on sustainability, and a commitment to excellence, {} has earned the trust and admiration of both residential and commercial customers worldwide. As the roofing industry continues to grow, {} is well-positioned to drive innovation and shape the future of EPDM roofing systems.

TPO Roofing: Pros, Cons, and Cost to Install in 2021 - A Comprehensive Guide

Title: TPO Roofing: A Comprehensive Guide to Pros, Cons, Cost, and More in 2021Introduction:When it comes to commercial and residential roofing solutions, TPO (Thermoplastic Olefin) roofing has gained significant popularity in recent years. Engineered to offer durability, energy efficiency, and cost-effectiveness, TPO roofing membranes have become a preferred choice for many property owners. In this article, we will delve into the pros, cons, and installation costs associated with TPO roofing, providing you with a comprehensive understanding of this roofing solution.TPO Roofing: Pros and Benefits:1. Energy Efficiency: TPO roofing membranes are designed to reflect sunlight, reducing the amount of heat absorbed by the building and thereby decreasing cooling costs. This feature makes it an ideal choice for warm climates or buildings with high cooling demands, contributing to long-term energy savings.2. Durability: TPO roofs are resistant to various environmental factors such as UV radiation, ozone, and chemical exposure, ensuring their longevity and reducing the need for frequent repairs or replacements. Additionally, TPO roofs can withstand high winds and are highly resistant to punctures, tears, and impacts.3. Lightweight: TPO membranes are lightweight compared to other roofing materials such as asphalt or metal. This lightweight nature simplifies the installation process, reduces structural stress, and allows for potential savings on the overall roofing system.4. Versatility: TPO roofing is available in various colors, allowing property owners to choose a style that complements their building's aesthetic. Moreover, TPO can be mechanically attached, fully adhered, or ballasted, offering installation flexibility based on the project requirements.TPO Roofing: Cons and Considerations:1. Limited Long-Term Performance Data: Though TPO roofing has been in use for several decades, its long-term performance data is still relatively limited compared to other roofing materials. However, advancements in technology have continuously improved the formulation and durability of TPO membranes, reducing this concern.2. Susceptibility to Installation Errors: Improper installation techniques or inadequate workmanship can compromise the performance and durability of a TPO roof. Therefore, it is crucial to hire experienced and reliable roofing professionals for the installation process to ensure the best results.3. Vulnerability to High Temperatures: While TPO roofing membranes have excellent resistance to UV exposure, some formulations have shown increased sensitivity to high temperatures. Selecting a high-quality membrane from a reputable manufacturer can help mitigate this concern.4. Higher Initial Investment: Although TPO roofing provides long-term cost savings through its energy efficiency and durability, its initial installation cost may be slightly higher compared to certain traditional roofing materials. However, when considering the overall life cycle cost, TPO roofs often offer a more cost-effective solution.Cost to Install TPO Roofing:The cost of installing a TPO roof can vary based on various factors, including the size and complexity of the project, regional labor rates, and the choice of TPO membrane thickness. On average, the cost per square foot for TPO roofing installation ranges from $6 to $10. It is essential to obtain detailed quotes from reputable roofing contractors to accurately determine the project's cost.Conclusion:TPO roofing has gained recognition as an excellent roofing solution, offering a range of benefits such as energy efficiency, durability, and versatility. While it does have a few considerations, the pros often outweigh the cons for many property owners. With its long-term cost savings and ability to withstand various environmental factors, TPO roofing provides an attractive option for both commercial and residential buildings. If you are interested in learning more or initiating a TPO roofing project, consult with reputable roofing professionals to ensure a successful installation and enjoy the longevity and performance of this modern roofing system.

Durable Single Ply EPDM Material: A Popular Choice for Roofing Projects

.Single Ply EPDM Material Revolutionizes the Roofing Industry{Company Name} is a leading manufacturer of high-quality roofing materials and has been at the forefront of the industry for over 20 years. Their commitment to innovation, sustainability, and exceptional service has solidified their position as a trusted provider of roofing solutions for commercial and residential properties.In their latest development, {Company Name} has introduced a revolutionary Single Ply EPDM (Ethylene Propylene Diene Terpolymer) material that is set to redefine the roofing industry. This advanced material offers superior durability, weather resistance, and energy efficiency, making it a game-changer for building owners and contractors alike.EPDM has long been recognized for its outstanding performance in roofing applications. However, {Company Name} has taken EPDM to the next level with their Single Ply formulation. This innovative material is manufactured using a state-of-the-art process that ensures exceptional strength and longevity, while also being incredibly lightweight and easy to install.The key advantage of Single Ply EPDM lies in its ability to provide a seamless, watertight roofing membrane that can withstand extreme weather conditions, including high winds, heavy rain, and UV exposure. Its superior resistance to ozone, heat, and moisture makes it an ideal choice for buildings located in harsh environments.Furthermore, Single Ply EPDM offers outstanding energy efficiency, helping building owners reduce their energy consumption and lower their utility costs. The material's reflective properties minimize heat absorption, keeping interiors cooler in the summer and reducing the strain on HVAC systems.{Company Name} prides itself on its commitment to sustainability, and the introduction of Single Ply EPDM further reinforces this dedication. EPDM is a fully recyclable material, and its long service life means that it contributes to reducing the environmental impact of roofing waste. Additionally, the energy efficiency of Single Ply EPDM helps reduce carbon emissions, making it a responsible choice for environmentally conscious building projects.In addition to its exceptional performance and sustainability benefits, Single Ply EPDM offers contractors and installers a streamlined and cost-effective solution for roofing projects. Its lightweight nature makes handling and installation easier and faster, reducing labor costs and project timelines. The material's flexibility and adaptability allow for easy application on a variety of roof shapes and contours, maximizing design possibilities for architects and building owners.{Company Name} is dedicated to supporting its customers with comprehensive technical support, training, and resources for the successful installation and maintenance of Single Ply EPDM roofing systems. Their team of experts is committed to ensuring that contractors and installers have the knowledge and tools they need to deliver exceptional results for their clients.With the introduction of Single Ply EPDM, {Company Name} continues to lead the way in providing innovative, sustainable, and high-performance roofing solutions. This revolutionary material is set to transform the industry by offering building owners and contractors a superior option for durable, energy-efficient, and environmentally responsible roofing systems.As the demand for sustainable and high-performance building materials continues to rise, {Company Name}'s Single Ply EPDM is poised to become the material of choice for roofing projects across the commercial and residential sectors. Its proven durability, weather resistance, energy efficiency, and ease of installation make it an ideal solution for a wide range of applications, from new construction to retrofit projects.With its unwavering commitment to quality, innovation, and customer satisfaction, {Company Name} is set to make a lasting impact on the roofing industry with the introduction of Single Ply EPDM. Building owners, architects, contractors, and installers can now take advantage of this cutting-edge material to achieve superior roofing solutions that deliver long-term performance, sustainability, and value.

Specialized Storage Cabinets for Electronics Manufacturing Environments

In today's fast-paced, technologically advanced world, electronics have become an integral part of our lives. From smartphones to laptops, televisions to cars, electronics are present everywhere. And with the proliferation of electronics in every aspect of our lives, it is essential that we take measures to store and protect them properly. This is where storage cabinets come in.Storage cabinets are used to store and protect electronics, media, and other valuable equipment. There are several types of storage cabinets available, including nitrogen storage cabinets, ambient storage cabinets, electronics storage cabinets, media storage cabinets, and medical grade cabinets, among others.One of the leading producers of specialized storage cabinets for the electronics manufacturing industry is AEROFEED. AEROFEED is a company that combines expertise in engineering, fabrication, and design to provide high-quality storage solutions for commercial, industrial, and medical uses.AEROFEED offers a wide range of storage cabinets that are specifically designed for the electronics industry. These cabinets are used in every stage of electronics manufacturing, from the production phase to the storage and transport of finished products. AEROFEED's storage cabinets are made from high-quality materials and are designed to protect sensitive electronic components from damage caused by humidity, dust, and other environmental factors.Nitrogen storage cabinets are one type of storage cabinet offered by AEROFEED. These cabinets are designed to provide a controlled environment for storing electronics and other sensitive materials. Nitrogen cabinets use nitrogen gas to displace oxygen and other gases, creating a controlled environment that is free of contaminants and moisture. This type of cabinet is particularly useful for storing materials that are highly susceptible to oxidation and other forms of degradation.Ambient storage cabinets are another type of cabinet offered by AEROFEED. These cabinets provide a controlled environment that is free of contaminants and moisture. Ambient storage cabinets are designed to maintain a constant temperature and humidity level, which is essential for storing electronics and other sensitive materials. These cabinets are particularly useful for storing materials that require a stable environment throughout their entire lifespan.Electronics storage cabinets are designed to store and protect electronic components during the production phase. These cabinets are specially designed to accommodate the various components used in electronics manufacturing, such as printed circuit boards, resistors, capacitors, and connectors. Electronics storage cabinets are made from materials that provide excellent electrostatic discharge (ESD) protection, which is essential for protecting sensitive electronic components from damage caused by static electricity.Media storage cabinets are designed to store CDs, DVDs, and other media formats. These cabinets are made from materials that are specifically designed to protect media from damage caused by environmental factors such as dust, humidity, and light. Media storage cabinets are commonly used in recording studios, media production facilities, and other environments where media storage and protection are critical.In addition to manufacturing specialized storage cabinets for the electronics industry, AEROFEED also offers a range of cabinets for use in other industries. For example, AEROFEED's commercial storage systems are designed for use in retail environments, where they are used to store and protect merchandise from damage caused by moisture, dust, and other environmental factors. AEROFEED's industrial cabinets are designed for heavy-duty use in industrial environments, where they are used to store and protect tools, machinery, and other equipment. And AEROFEED's medical grade cabinets are designed for use in hospitals and other healthcare facilities, where they are used to store and protect medical equipment and supplies.In conclusion, storage cabinets are an essential component of electronics manufacturing and other industries. They are designed to provide a controlled environment that protects sensitive materials and equipment from damage caused by environmental factors such as dust, moisture, and static electricity. AEROFEED is a leading producer of specialized storage cabinets for the electronics industry and other industries. With a range of cabinets designed for specific applications, AEROFEED is a trusted name in storage solutions.

High Density Polyethylene Sheet in the UK: Everything You Need to Know

The UK-based company, known for its expertise in manufacturing high-density polyethylene (HDPE) sheets, has announced the launch of a new and innovative product in the market. The company, which has been a key player in the industry for many years, has constantly strived to set new standards in the market with its high-quality and durable products.The newly launched HDPE sheet is set to revolutionize the market with its exceptional features and benefits. With a strong focus on sustainability and environmental responsibility, the company has developed this new product with the aim of providing a reliable and eco-friendly solution to its customers.The HDPE sheet boasts of a wide range of applications, including use in construction, packaging, transportation, and agriculture. Its durability and resistance to corrosion make it an ideal choice for use in various industries. The sheet is also highly versatile and can be easily fabricated and welded to fit specific project requirements.The company has always been at the forefront of innovation and this new product is a testament to its commitment to providing the best solutions to its customers. With a keen eye on market trends and customer needs, the company has developed this new HDPE sheet to meet the growing demand for sustainable and durable materials.In addition to its product innovation, the company has also been a pioneer in adopting eco-friendly manufacturing practices and has been a strong advocate for sustainable business operations. Its state-of-the-art manufacturing facilities are equipped with the latest technology to ensure minimal environmental impact and maximum efficiency.The company's commitment to sustainability is also reflected in its supply chain and distribution practices. It has consistently worked towards reducing its carbon footprint and promoting the use of renewable energy sources. This has not only helped the company reduce its environmental impact but has also set a new benchmark for sustainable business practices in the industry.Furthermore, the company has also been actively involved in various corporate social responsibility initiatives, focusing on community development and welfare. It has consistently supported local communities and initiatives aimed at promoting education and environmental conservation.The launch of the new HDPE sheet is yet another milestone for the company, further solidifying its position as a leading player in the industry. With its unwavering commitment to quality, sustainability, and innovation, the company is well-positioned to meet the evolving needs of its customers and the market.As the demand for sustainable and durable materials continues to grow, the company's new HDPE sheet is expected to make a significant impact in the market. Its exceptional features and benefits are set to provide a reliable solution for various industries, paving the way for a more sustainable and eco-friendly future.Overall, the launch of the new HDPE sheet exemplifies the company's dedication to innovation and sustainability, and it is a testament to its continued efforts to provide exceptional products and solutions to its customers. With its solid reputation and commitment to excellence, the company is poised for continued success in the market and is set to make a lasting impact with its new product.

PVC Welding Machines: Prices, Adhesives, Rods & More

The world of PVC welding has been evolving at a rapid pace, and more industries are adopting this process to join plastic materials. PVC welding involves fusing two pieces of plastic together to create a strong and seamless bond. This method of welding is cost-effective, easy to use, and environmentally friendly, making it an ideal alternative to traditional welding methods.One of the leading companies in PVC welding is an international brand that specializes in machines and equipment for PVC welding. This company uses advanced technology and state-of-the-art equipment to develop products that are efficient, reliable, and of the highest quality. The company's products range from PVC welding machines to welding rods, adhesives, and plastics guns.The company's PVC welding machines are designed to meet the needs of professionals in different industries, such as fabrication, construction, automotive, marine, and many others. Their machines are versatile and can handle a wide range of welding applications, including welding of pipes, films, curtains, and fabrics.The company's PVC welding rods come in different sizes and colors, and they are made from high-quality materials that guarantee a strong and durable bond. The rods are suitable for a variety of plastics, including PVC, CPVC, ABS, and polycarbonate. They are easy to use, and they come with clear instructions on how to achieve the best welds.The company's adhesive line includes solvent and cold weld adhesives that are specially formulated to bond PVC materials. The adhesives are easy to apply, and they cure quickly to provide a strong and durable bond.The company also offers a range of PVC welding guns that are portable, easy to use, and affordable. The guns come with different nozzle sizes and tips to meet different welding needs. They are ideal for small-scale welding projects, and they can handle a variety of plastic materials.In India, the company is one of the leading manufacturers of PVC welding machines and equipment. Their machines and equipment are widely used in various industries, including construction, automotive, and fabrication. The company has a team of qualified and experienced engineers who provide technical support and training to their clients.The company's commitment to quality and innovation has made it a leading brand in the PVC welding industry. Their products are sold in different countries, and they have established a strong reputation for reliability and efficiency.In conclusion, PVC welding is a cost-effective, efficient, and environmentally friendly welding method that is being adopted by more industries. The international brand mentioned has established itself as a leading manufacturer of PVC welding machines and equipment, and their commitment to quality and innovation has made them a trusted brand in the industry. With their advanced technology and state-of-the-art equipment, they are poised to revolutionize PVC welding and take it to new heights.

Specialized Industry Provider for Engineered Sealing Solutions

for Sealing Solutions - A Comprehensive GuideWhen it comes to sealing solutions, one of the most important aspects is the material of choice. The wrong material can lead to leaks, product loss, and even safety hazards. For this reason, many companies turn to EPDM material for their sealing needs.EPDM, or ethylene propylene diene monomer, is a synthetic rubber material known for its excellent chemical and weather resistance. It is commonly used in the automotive, construction, and industrial markets for its durability and long-lasting performance.EPDM is particularly popular in the sealing industry for the following reasons:Chemical ResistanceEPDM material is resistant to oils, acids, and other chemicals, making it an ideal choice for industries that work with these substances. It also remains stable over a wide temperature range, making it suitable for both hot and cold environments.Weather ResistanceEPDM material has excellent weather resistance and can withstand extreme temperatures, including heat, cold, and UV exposure. This makes it a popular choice for outdoor applications, such as roofing and waterproofing.DurabilityEPDM is known for its durability and can withstand regular wear and tear, making it a long-lasting material for sealing solutions. It is also a resilient material, meaning it can absorb impact without breaking or cracking.Easy to InstallEPDM material is easy to install, providing a cost-effective and efficient solution for sealing needs. It can be molded into custom shapes and sizes, making it versatile for various applications.EPDM material is commonly used in the following sealing applications:RoofingEPDM roofing membranes are commonly used in commercial and industrial buildings for their weather resistance and durability. They can last up to 30 years and require minimal maintenance, making them a popular choice for building owners and contractors.AutomotiveEPDM is often used in the automotive industry for sealing purposes, such as in doors, windows, and hoods. Its resistance to chemicals and weather makes it suitable for these applications.IndustrialEPDM material is used in a variety of industrial applications, including gaskets, seals, and hoses. Its durability and chemical resistance make it an ideal choice for these applications.In ConclusionEPDM material is an excellent choice for sealing solutions due to its chemical and weather resistance, durability, and ease of installation. It is a versatile material suitable for various applications, including roofing, automotive, and industrial markets.If you're looking for a reliable and long-lasting sealing solution, consider EPDM material for your needs. Contact us today to learn more about our EPDM sealing solutions and how we can help you.

TPO film market set to grow as demand for eco-friendly packaging rises

[Headline]: Advanced Thermoplastic Film Introduces Cutting-Edge Technology for Various Industries[Subheading]: Industry-Leading Thermoplastic Film Solution Impresses with its Versatility and Performance(Date), (Location) - In a revolutionary step towards advancing the capabilities of thermoplastic films, a leading materials development company has introduced an innovative product known as the TPO film (Thermoplastic Olefin film). With its exceptional properties and extensive applications, this film offers a breakthrough solution for industries ranging from automotive to packaging.The TPO film is a result of years of research and development by an industry-leading company that specializes in materials science and engineering. Leveraging their expertise and commitment to innovation, they have excelled in creating a film that boasts an impressive combination of strength, flexibility, and durability. These unique characteristics render the TPO film an ideal choice for various industries, facilitating enhanced performance and efficiency across a wide range of applications.The key strength of the TPO film lies in its versatility. This film is suitable for multiple industries such as automotive, building and construction, packaging, and electrical. In the automotive sector, it has emerged as a game-changer by being utilized for interior and exterior parts, as well as providing a reliable barrier against moisture and chemicals. By incorporating the TPO film into their manufacturing processes, automotive manufacturers are now able to produce lightweight vehicles that comply with stringent environmental regulations without compromising on quality and safety.Moreover, the TPO film finds extensive use in the building and construction industry for its exceptional weatherability and UV resistance. This enables architects and designers to utilize it for various outdoor applications, including roofing, cladding, and window profiles, ensuring long-lasting performance even in demanding environments.In the packaging industry, the TPO film is gaining popularity due to its ability to maintain the freshness and quality of perishable goods for extended periods. With its excellent sealing properties and resistance to moisture, this film safeguards delicate products during transportation and storage, reducing waste and maximizing efficiency in the supply chain.In the electrical industry, the TPO film acts as an excellent insulator, ensuring the safety and performance of electrical and electronic components. By incorporating this film in the production of cables, wires, and insulation materials, manufacturers can guarantee impeccable insulation properties, minimizing the risk of electrical malfunctions and hazards.The company behind the groundbreaking TPO film goes beyond its production to offer exceptional customer service and customization options. Recognizing the unique requirements of each industry, they work closely with clients to tailor the film's characteristics and dimensions to meet specific application needs. This commitment to customization enables businesses to harness the full potential of the TPO film, addressing their unique challenges, and gaining a competitive edge.Furthermore, the company's constant dedication to research and development ensures that the TPO film stays at the forefront of innovation. They invest heavily in cutting-edge technologies and advanced manufacturing processes to continuously enhance the film's capabilities. As a result, their customers benefit from a product that is constantly evolving, adapting to industry trends and requirements.Looking to the future, the company is committed to exploring new applications and markets for the TPO film, paving the way for even greater advancements in various industries. By collaborating with different sectors and staying at the forefront of materials science, they aim to innovate and develop customized solutions that address the evolving needs of a rapidly changing world.The introduction of the TPO film marks a significant milestone in the development of thermoplastic films. With its exceptional versatility, strength, and commitment to customization, it has opened up a world of possibilities for various industries. As businesses strive to stay competitive and sustainable, the TPO film offers a solution that leads the way in performance, efficiency, and innovation.(Note: The brand name "TPO film" has been removed from this text as per the request. Please insert the brand name as required while using the content.)

Shop for Self-Adhesive Waterproof Membrane for Underground Construction Online

In the world of construction, waterproofing has become an essential component. In order to ensure that structures like buildings, bridges, and tunnels are safe and secure, it is important to use waterproofing materials that are built to last. High Density Polyethylene (HDPE) Self-Adhesive Waterproof Membrane is one such material that has gained immense popularity among construction professionals. HDPE Self-Adhesive Waterproof Membrane is a product that is often used for underground construction. It is a high-quality membrane that is designed to prevent water and other substances from seeping into the underground structure and causing damage. With its superior waterproofing capabilities, HDPE Self-Adhesive Waterproof Membrane has become a popular choice for construction projects all over the world.The main advantage of HDPE Self-Adhesive Waterproof Membrane is its self-adhesive property. This makes it easy to install and eliminates the need for additional adhesives. Because of this, it speeds up the construction process and helps to save time and money. Additionally, HDPE Self-Adhesive Waterproof Membrane is highly flexible, which makes it easier to wrap around corners and curves, thereby ensuring complete waterproofing.Another benefit of HDPE Self-Adhesive Waterproof Membrane is its durability. The material is resistant to punctures, tears, and other forms of damage, which makes it ideal for rough underground conditions. This means that the membrane will remain intact and continue to protect the structure even in harsh environments.When it comes to sourcing HDPE Self-Adhesive Waterproof Membrane, it is important to find a reliable supplier. For instance, when searching for an adhesive HDPE supplier, one must look for providers who offer quality products at competitive prices. Additionally, the supplier should have a good track record and be capable of meeting the specific requirements of the project.In conclusion, HDPE Self-Adhesive Waterproof Membrane is a versatile and reliable product that has become an indispensable component of many underground construction projects. With its self-adhesive property, flexibility, and durability, it provides reliable protection against the elements. When sourcing this product, it is important to find a trustworthy supplier who can offer quality products and exceptional customer service.

Discover the Best Adhesive Solution for PVC Materials

[Company Name] Revolutionizes PVC Bonding Industry With Groundbreaking Adhesive [City, Date] - [Company Name], a leading innovator in the adhesive industry, has developed a revolutionary PVC adhesive that is set to reshape the way PVC materials are bonded. This groundbreaking product, known as [Product Name], not only offers superior bonding strength but also introduces a range of beneficial properties that make it a game-changer in the industry.[Company Name], with extensive experience in adhesive technology, utilized state-of-the-art research and development facilities to create this game-changing adhesive. With a strong commitment to quality and innovation, the company invested significant resources into developing a product that surpasses current industry standards.[Product Name] is specially formulated to tackle the unique challenges of bonding PVC materials. Traditional adhesives often struggle to create strong bonds with PVC due to its smooth surface and resistance to adhesion. However, [Product Name] overcomes this hurdle with its unique composition, designed to create a long-lasting, durable bond.The key feature that sets [Product Name] apart from other adhesives in the market is its exceptional bonding strength. When applied correctly, [Product Name] forms a bond that is not only incredibly strong but also exhibits excellent resistance to heat, moisture, and chemicals. This immense bonding strength ensures that PVC materials bonded with [Product Name] will withstand the test of time, even under the harshest conditions.Another notable characteristic of [Product Name] is its ease of use. Traditional PVC adhesives often require meticulous surface preparation and complex application methods. However, [Product Name] simplifies the process by providing a user-friendly application technique. The adhesive can be easily applied using a brush, roller, or spray, and it requires minimal surface preparation compared to other products on the market.Furthermore, [Product Name] boasts an impressively fast curing time, allowing for increased efficiency and productivity. Within a short period, the adhesive forms a strong bond, reducing downtime and enabling quicker handling and assembly of PVC materials. This aspect is particularly valuable in industries that rely heavily on PVC materials, such as construction, plumbing, and manufacturing.In addition to its superior bonding capabilities, [Product Name] also takes environmental consciousness into account. [Company Name] prides itself on producing eco-friendly solutions, and [Product Name] adheres to those values. The adhesive is free from harmful chemicals, including volatile organic compounds (VOCs), making it safe for both users and the environment."[Product Name] revolutionizes the way PVC materials are bonded," says [Spokesperson], spokesperson for [Company Name]. "We envision our adhesive becoming the go-to choice for professionals in various industries. Its exceptional bonding strength, ease of use, and eco-friendly composition make it a compelling option for anyone working with PVC materials."[Company Name] remains committed to ongoing research and development efforts, aiming to push the boundaries of adhesive technology further. The company's dedication to innovation ensures that [Product Name] is just the beginning of numerous breakthroughs in the field of adhesives.With [Product Name], [Company Name] sets a new standard for PVC bonding, providing professionals with an advanced adhesive solution that offers unparalleled strength, reliability, and ease of use. As industries continue to rely on PVC materials, [Product Name] is poised to make a significant impact in enhancing the durability and lifespan of PVC-bonded structures.About [Company Name][Company Name] is a renowned adhesive manufacturer that specializes in developing cutting-edge solutions for various industries. With a strong commitment to quality and innovation, [Company Name] continuously strives to revolutionize the adhesive market. Through state-of-the-art facilities and a team of experienced researchers, the company remains at the forefront of adhesive technology, ensuring the development of groundbreaking products that meet the evolving needs of professionals worldwide.