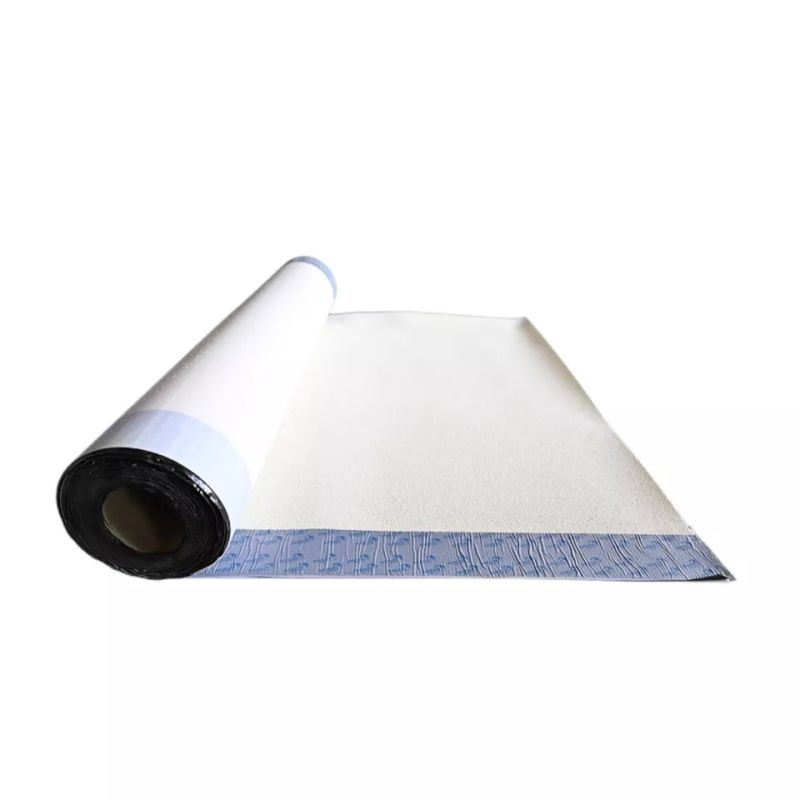

- High anti-seepage coefficient 1x10-17cm/s.

- Excellent heat and cold resistance,the operation environment temperature is up to -70°C-110°C.

- Excellent chemical stability, can resist corrosion of strong acid, alkali and oil.

- With good tensile strength,can be meet high standars of projects requirements.

- With strong climate resistance and anti-aging properties.

- With strong tensile strength and elongation at break, can be used in extremely geological and climatic conditions.

- Adapt to geological uneven settlement strain.

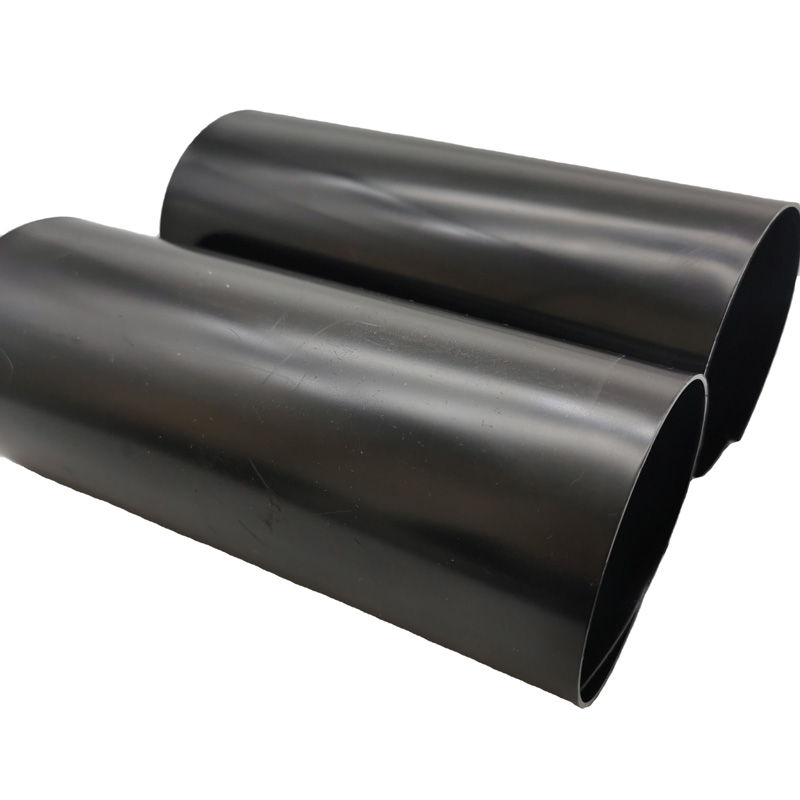

- HDPE is a very technical product to work with. It must be installed by certified welding technicians using specialized welding equipment to ensure performance.

- Installations are temperature and poor weather sensitive.

- 60 mil HDPE liner is the staple of the industry and is suitable for most applications.

| TESTED PROPERTY | TEST METHOD | FREQUENCY | UNIT ENGLISH METRIC | VALUE ENGLISH(METRIC |

| Thickness Lowest individual reading | ADTM D 5199 | every roll | mil(mm) | 60(1.50) 54(1.35) |

| Density | ASTM D1503 | 200,000lbs(90,000kg) | g/m³(mil) | 0.94 |

| Tensile properties (each direction Strength at break Strength at yield Elongation at break Elongation at yeild | ASTM D 6692 ,Type IV Dumbbell,2 ipm (50mm/min) G.L 2.0min(50mm) G.L.1.3min(33mm) | 200,000ibs(90,000kg) | lb/in-width(N/mm) lb/in-width(N/mm) % % | 228(40) 126(22) 700 12 |

| Tear Resistance | ASTM D 1004 | 45,000ibs(20,000kg) | Ib(N) | 42(187) |

| Puncture Resistance | ASTM D 4833 | 45,000ibs(20,000kg) | Ib(N) | 108(480) |

| Carbon Black Content | ASTM D 1063*/4218 | 20,000ibs(9,000kg) | %(range) | 2.0-3.0 |

| Caron Black Dispersion | ASTM D 5596 | 45,000ibs(20,000kg) | Note | |

| Notch Constant Tensile Load | ASTM D 5397 Appdenix | 20,000ibs(9,000kg) | hr | 300 |

| Oxidative Induction Time | ASTM D 3895 ,200℃ O2 , atm | 20,000ibs(9,000kg) | min | > 100 |

| TYPICAL ROLL DIMESIONS | ||||

| Roll Length | ft(m) | 164.04(50) | ||

| Roll Width | ft(m) | 19.68(6) | ||

| Roll Area | ft²(m²) | 3229.17(300) | ||

| Notes | ||||

| ** Roll lengthe and width have a torance of ±1% | ||||

| ** All geomembranes have dimesional stability of ±2% when tested according to ASTM 1204 and 1204 and LTB of < -77°C when tested according to ASTM D746 | ||||

- Irrigation ponds, canals, ditches & water reservoirs.

- Mining heap leach & slag tailing ponds.

- Golf course & decorative ponds.

- Landfill cells, covers & caps.

- Wastewater lagoons.

- Secondary containment cells / systems.

- Liquid containment.

- Environmental containment.

- Soil Remediation.

Over 35 years experience of manufacturing,

Professional technical and service team

Supplying all kinds of waterproofing geomemrbrane

Online factory check is acceptable

Customized requests are welcomed .

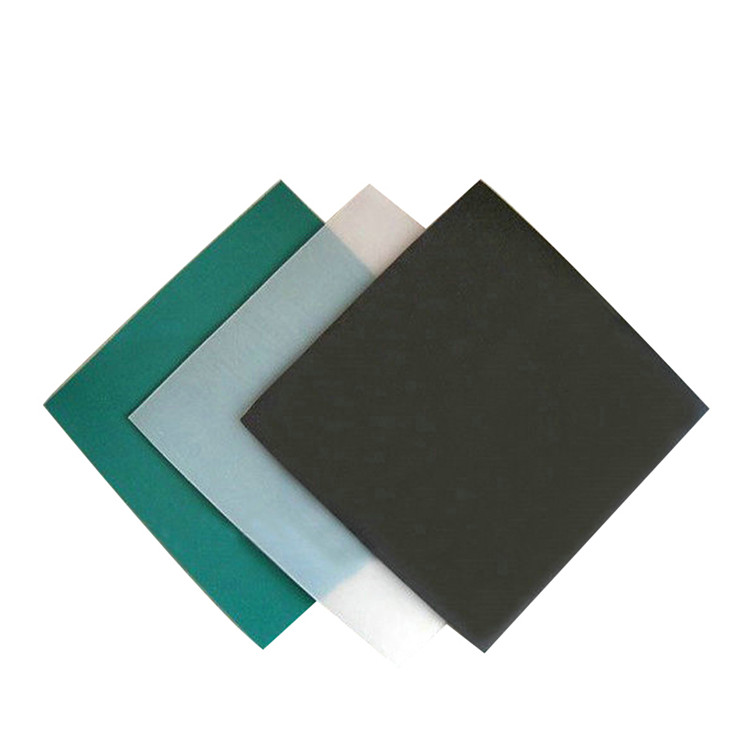

HDPE geomembrane,TPO ,PVC,EPDM membrane are on sale