| TESTED PROPERTY | TEST METHOD | FREQUENCY | UNITENGLISH(METRIC) | VALUEENGLISH(METRIC) | |||

| ThicknessLowest individual reading | ASTMD 5994 | every roll | mil (mm) | 100(2.50)90(2.25) | |||

| Density | ASTMD 1505 | 200,000 Ib(90,000 kg) | Glcm3 (min) | 0.940 | |||

| Tensile Properties(Each Direction)Strength at Break Strength at Yield Elongation at Break Elongation at Yield | ASTM D 6693,Type lvDumbell. 2 ipmG.L.2.0in (50mm) G.L. 1.3in (33mm) | 20,000 lb(9,000 kg) | lb/in-width (N/mm)lb/in-width(N/mm) % % | 150(26)210(37) 100 12 | |||

| Tear Resistance | ASTMD 1004 | 45,000 lb (20,000 kg) | lb(N) | 70(311) | |||

| Puncture Resistance | ASTM D 4833 | 45,000 lb (20,000 kg) | lb(N) | 150(667) | |||

| Carbon Black Content | ASTMD 1603*/4218 | 20,000 lb (9,000 kg) | %(range) | 2.0-3.0 | |||

| Carbon Black Dispersion | ASTM D 5596 | 45,000 lb (20,000 kg) | Note") | ||||

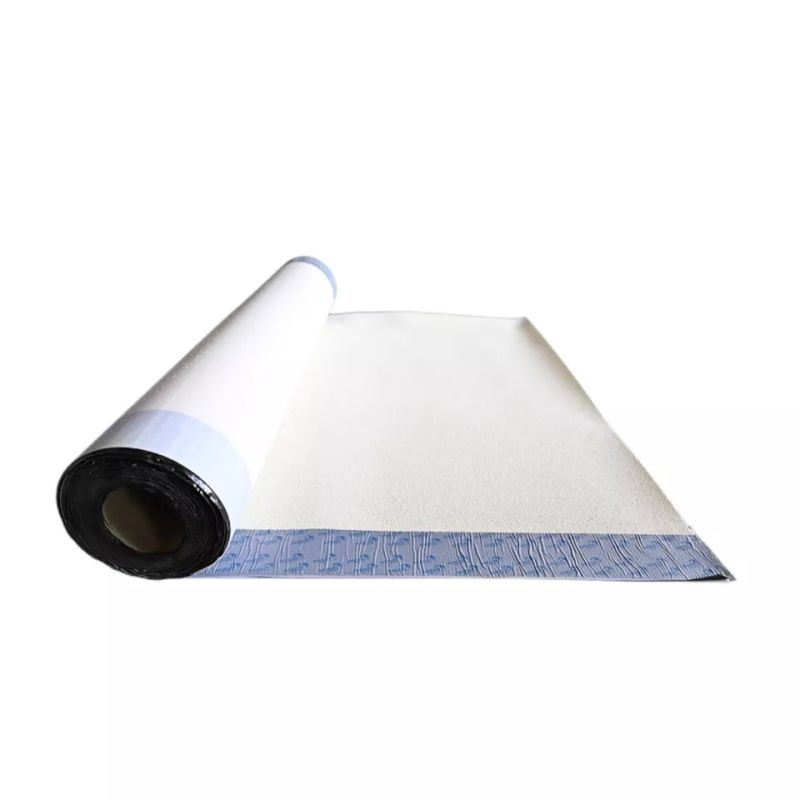

| Asperity Height | ASTMD 7466 | Second roll | mil (mm) | 18(0.45) | |||

| Notched Constant TensileLoad(2) | ASTM D 5397,Appendix | 200,000 Ib(90,000 kg) | hr | 500 | |||

| Oxidative lnduction Time | ASTM D 3895.200"c;o2. 1 atm | 200,000Ib(90,0O0kg) | hr | >100 | |||

| TYPICAL ROLL DIMENSIONS | |||||||

| Roll Lenath(3) | Double-Sided Textured | ft (m) | 164(50) | ||||

| Single-Sided Textured | ft (m) | 164(50) | |||||

| Roll Width(3) | ft (m) | 19(5.8) | |||||

| Roll Area | Double-Sided Textured | f2(m2) | 3,116(290) | ||||

| Double-Sided Textured | f2(m2) | 3,116(290) | |||||

- Irrigation ponds, canals, ditches & water reservoirs

- Mining heap leach & slag tailing ponds

- Golf course & decorative ponds

- Landfill cells, covers, & caps

- Wastewater lagoons

- Secondary containment cells/systems

- Liquid containment

- Environmental containment

- Soil Remediation

- HDPE is a very technical product to work with. It must be installed by certified welding technicians using specialized welding equipment to ensure performance.

- Installations are temperature and poor weather sensitive.

- 40 mil HDPE liner requires extra effort to ensure that the subgrade is in excellent condition. It is suitable as an upgrade from products like the 20 mil RPE for larger installations and is an excellent secondary containment liner on multi-layer systems (for example; subgrade, geotextile layer, 40 mil HDPE layer, drainage net layer, 60 mil HDPE layer, geotextile layer, fill.)

- 60 mil HDPE liner is the staple of the industry and is suitable for most applications.

- 80 mil HDPE liner is a thicker design for more aggressive subgrades.

HDPE geomembrane liners are the preferred product for lining projects. HDPE liners are resistant to many different solvents and are the most widely used geomembrane liner in the world. Although HDPE geomembrane is less flexible than LLDPE, it provides higher specific strength and can withstand higher temperatures. Its exceptional chemical and ultraviolet resistance properties make it an extremely cost-effective product.